Most of us know Mooneyes because the model behind Japan’s most prestigious customized bike and automobile present. However the firm’s historical past might be traced again to Fifties America, when its founder, Dean Moon, began making a reputation for himself within the Southern Californian scorching rod scene.

Certainly one of Moon’s most notable creations was the Mooneyes Streamliner. With an aesthetic someplace between artwork deco and futuristic (for the 60s), the Streamliner was a land-speed racing automobile with aerodynamic bodywork and a shiny yellow paint job. It was additionally the inspiration for this outlandish twin-engined Triumph drag bike, constructed by James Rogers in Gloucestershire, England.

James is way from a typical customized bike builder. He damp-proofs basements for a dwelling, constructing customized bikes after hours as a artistic outlet out of a single-car storage, armed with little greater than a grinder, welder, and heaps of creativeness. “I’ve no engineering background,” James admits. “I simply have a go.”

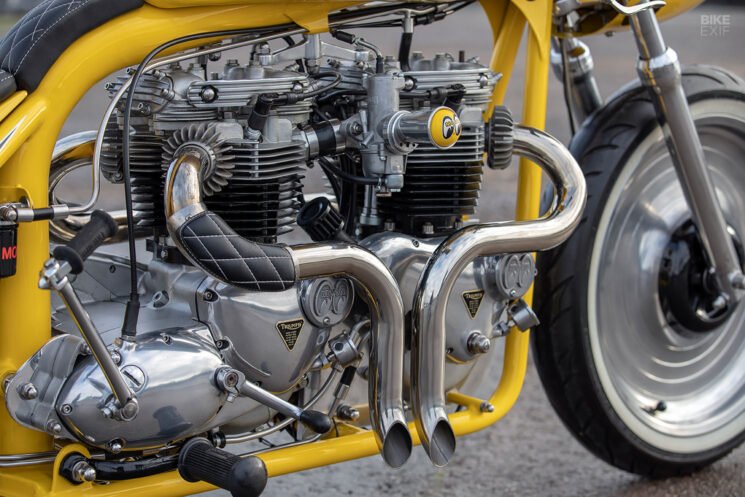

“This challenge began off with two broken Triumph TR6 engine casings that had been storage wall artwork. Then I used to be given an oil-in-frame T120R whose con-rod had a disagreement with the crank. I began twin-engine drag bikes from the 60s, 70s, and 80s, to see how they linked the 2 engines collectively—that is once I seen that nobody had ever put a Triumph pre-unit and a Triumph unit motor collectively.”

“With this in thoughts, I wished to construct a road-legal twin-engine bike with a scorching rod theme. That’s the place the Mooneyes inspiration got here in. I’m an enormous fan of Mooneyes and a good larger fan of the Mooneyes Streamliner, which is what I based mostly the bike on.”

James’ first job was to manufacture a brand new chassis across the oil-bearing part of the Triumph T120R’s body. So he constructed a body jig out of boxed metal sections from his native scrapyard, after which ordered tubing to make use of for the body itself. “I known as a man I used earlier than to bend tubing, and requested him if he may bend the tubes for me,” he remembers. “He mentioned, ‘The secret is subsequent door to the unit, go and assist your self,’ which I did.”

“I didn’t need the bike lengthy like a standard drag bike—I wished to make it rideable for the road. So I appeared on the net and located an alternator that was two-and-a-half inches in diameter, which meant I may set the handlebars three inches nearer to me and transfer the engines again within the body. With this in thoughts, I began to weld the body up.”

The bespoke body incorporates a inflexible tail with a set of 2001-spec Harley Sportster yokes and forks up entrance. It rolls on a set of restored Harley V-Rod wheels, geared up with chrome steel brake discs, fashionable Triumph calipers, and handmade braided brake strains.

James occurred upon the wheels (and the bike’s bodywork) by probability whereas visiting the close by Cheltenham Harley-Davidson showroom. “I obtained chatting to the blokes about my challenge and what I used to be on the lookout for, and so they kindly took me to the again of the workshop,” he tells us. “It was like Aladdin’s cave—it had every little thing I wanted, however with a slight drawback…”

“Just like the components I began this bike with, every little thing was broken. There was a dented Harley Highway King petrol tank, a twisted and dented Harley Highway King entrance mudguard, and water-damaged Harley V-Rod wheels. So I solely paid scrap metallic costs for them.”

Armed with the beat-up donor components, plus a drag racing cone fairing that he satisfied a enterprise associate of a buddy to promote to him, James started beating his two-wheeled Streamliner into form. He reduce and shut the Harley tank to match its width to the fairing, earlier than knocking out the dents and fabricating a brand new tunnel and mounts. Then he restored the mangled Highway King entrance fender, flipping round and modifying it closely to show it right into a tailpiece.

As soon as all of the bits had been on the body, James realized that he didn’t just like the hole between the seat and the gas tank. So he took a piece of chrome steel exhaust tubing and used it as a base for a small tummy pad. “Now it appeared proper—and I had someplace to relaxation my stomach and never scratch the paintwork,” he provides.

When it got here to constructing the engines, James had a mammoth process forward of him. All he had firstly had been the 2 broken TR6 casings—one unit, and one pre-unit—and a pair of dual-inlet T120 heads. “I had no internals for these engines,” he says, “so I made a cellphone name to Miles at Autovalues Engineering, and chatted about what I wished to realize.”

“That’s when he mentioned that he had simply cleared out his late father’s storage, and located two units of Morgo con-rods, nonetheless of their containers. I needed to have them—together with two units of barrels and pistons, two pairs of tappet blocks, rotary oil pumps for a pre-unit and unit, stainless base nuts for the barrels, two distant oil filters, and a load of running-in oil. I believed, ‘What have I began?’”

A visit to Ebay (which James refers to as “The Bay of Desires”) produced matching light-weight late-60s cranks, E3134 cams, type-R tappets, push rods, and cam gears. James wished the association to look symmetrical, so he reversed the rear engine’s head—that manner, both sides of the bike would function one carb and a pair of downturned exhausts. After a second journey to Ebay to order some mandrel-bent exhaust sections and a TIG welder, the heavy lifting may start.

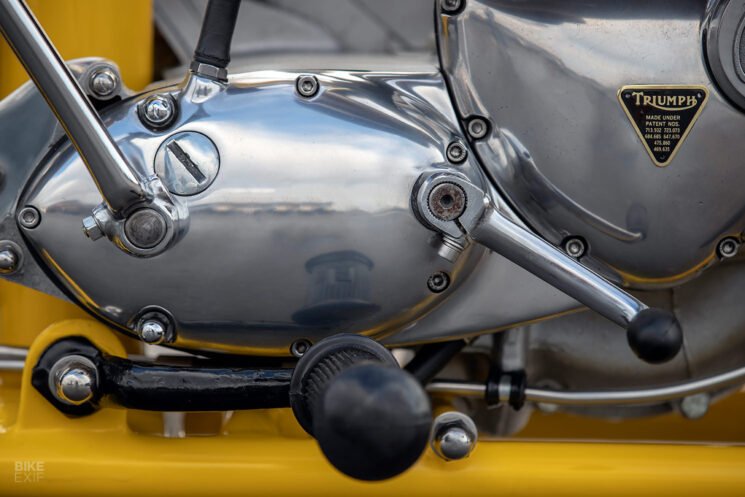

“The primary one-off job was to place a unit ignition housing right into a pre-unit timing cowl, so I needed to make a jig from some flat alloy plate that I obtained from KJE Engineering. I used to be shocked to search out out that a lot of the bolt holes from every timing cowl matched, which made the job rather a lot simpler. So I reduce a unit timing cowl up for the housing (I do know it’s improper to chop previous Triumph components, however wants should), cleaned it up on my lathe, and welded it into the pre-unit timing cowl.”

Because the challenge unfolded, James invented numerous workarounds akin to this one. The pre-unit casing had been broken when somebody had tried to knock out the primary bearing with out first eradicating the circlip—so he employed his buddy Neil to assist him engineer a bolt-in bearing retainer. And the unit casing was so badly cracked, that he ended up mating it to half of one other Triumph casing; discovered on one more journey to The Bay of Desires.

James’ subsequent mission was to hyperlink the engines collectively—for this, he turned to a different buddy, Carl Harris of Harris Scorching Rod Components, who lives down the street from him. “I used to be round his storage for a chat and cup of tea whereas he was sorting automobile components out for a swap meet once I seen two pulleys for a small block Chevy in a bread crate. After a chat, and £5 every later, I had the beginning for linking the engines collectively.”

“I turned the tooth off of two entrance sprockets and machined them flat in order that I may bolt the pulleys onto them. I measured up for a belt and ordered one, however when the belt arrived, the issue of the right way to take the slack out of the belt was raised. So I went again onto the web to do a little analysis, the place I discovered an Audi A6 cam belt tensioner—nevertheless it had a small curler.”

On the cusp of getting his twin-engined creation working, James despatched a drawing of the ultimate pulley he wanted to KJE Engineering to fabricate. That’s when he hit the primary in a collection of main hurdles; a worldwide pandemic that shut every little thing down and stalled the Streamliner challenge for 16 months.

No sooner had James obtained the bike again on monitor, than he hit one other brick wall. He was about to order the compact alternator that he had deliberate the bike’s ergonomics round, however he came upon that the corporate had made an error. “The 2-and-a-half-inch diameter was for the part that matches contained in the casing. I virtually gave up ending the bike… however I didn’t.”

“I obtained chatting to Allen Millyard whereas I used to be filming with Henry Cole for The Bike Present, and he mentioned he runs most of his bikes on a complete loss system, and makes use of 18650 batteries [cylindrical Lithium-ion cells commonly used in electronic devices]. I emailed some battery corporations and just one from Bristol got here again to me saying they might assist. They mentioned that what I used to be working on the bike, the battery packs would final one-and-a-half hours—so I ordered two together with a charger.”

As soon as once more motivated to complete the bike, James ordered a pair of brand-new Amal carbs from Burlen Inc., and two digital ignitions from Tri Spark in Australia. He’d heard that the Mooneyes crew was coming to an area present in just a few weeks’ time, so he used that as his deadline. However alas, the Streamliner wouldn’t begin—and James had no thought why.

Resigned to the concept that Mooneyes must see a non-running bike, James turned his focus to finishing the non-mechanical duties on his listing. The bike had been painted midway via the construct by Chris Davison (as a result of James couldn’t wait to see what it will appear to be), however the yellow body had picked up some chips alongside the way in which. So the bike went to an area physique store, As much as Scratch, for touch-ups, whereas the seat was upholstered by Customized Coach Trimming. Allen Collins had the duty of sprucing and plating the myriad aftermarket, modified, restored, and handmade components that adorn this excellent contraption.

The bike was put again collectively, taken the present, adored by all, after which returned to James’ storage to lastly troubleshoot the issue. After numerous hours spent checking each conceivable level of failure, he stumbled upon the answer on-line. “I used to be studying concerning the café racer boys utilizing pre-unit kick-starters on larger bored motors, so I believed I’d give one a go. Second kick, and away she went.”

James’ Mooneyes-inspired, twin-engined, garage-built Streamliner shouldn’t be solely a marvel of engineering and a tribute to a legendary car, but additionally a testomony to his creativeness, ingenuity, and perseverance, and that of his ever-supportive circle of associates.

“This has taken me seven years to finish and all I wish to do now could be trip it and present it off,” he concludes. And so it’s best to, James.

Pictures by, and with honest gratitude to, Del Hickey

James want to thank the blokes at KJE Engineering, Miles at Autovalves Engineering, Andy Barnett for serving to with the welding, and my spouse for placing up with me within the storage on a regular basis.

Trending Merchandise